Introduction :

Valves are critical components in various industries, ensuring the smooth flow of liquids, gases, and other media. Keeping your valves durable and functioning optimally is essential for maintaining efficiency and reducing downtime. As a trusted valve industries supplier, PT Edelweiss Utama Karya, the official distributor of Weissmiller valves, understands the importance of proper valve maintenance. In this article, we’ll share 5 essential tips to ensure your valves remain durable and functioning at their best.

1. Conduct Regular Inspections

- Why It’s Important: Regular inspections help identify potential issues like leaks, corrosion, or wear and tear before they become major problems.

- What to Do: Schedule routine checks for all valves in your system. Look for signs of damage, such as cracks, rust, or unusual noises during operation.

- Pro Tip: Use diagnostic tools like ultrasonic detectors to identify internal issues that aren’t visible to the naked eye.

2. Clean Valves Periodically

- Why It’s Important: Dirt, debris, and sediment can accumulate inside valves, leading to blockages or reduced efficiency.

- What to Do: Disassemble valves (if possible) and clean them thoroughly. Use appropriate cleaning agents that won’t damage the valve materials.

- Pro Tip: For valves in harsh environments, consider installing filters or strainers to prevent debris from entering the system.

3. Lubricate Moving Parts

- Why It’s Important: Proper lubrication reduces friction between moving parts, preventing wear and ensuring smooth operation.

- What to Do: Use the recommended lubricant for your valve type. Apply it to stems, threads, and other moving components regularly.

- Pro Tip: Avoid over-lubrication, as excess lubricant can attract dirt and cause blockages.

4. Monitor Operating Conditions

- Why It’s Important: Valves are designed to operate within specific pressure, temperature, and flow rate ranges. Exceeding these limits can cause damage.

- What to Do: Install pressure gauges and temperature sensors to monitor operating conditions. Ensure valves are used within their specified limits.

- Pro Tip: For extreme conditions, consider using valves made from specialized materials like stainless steel or alloys.

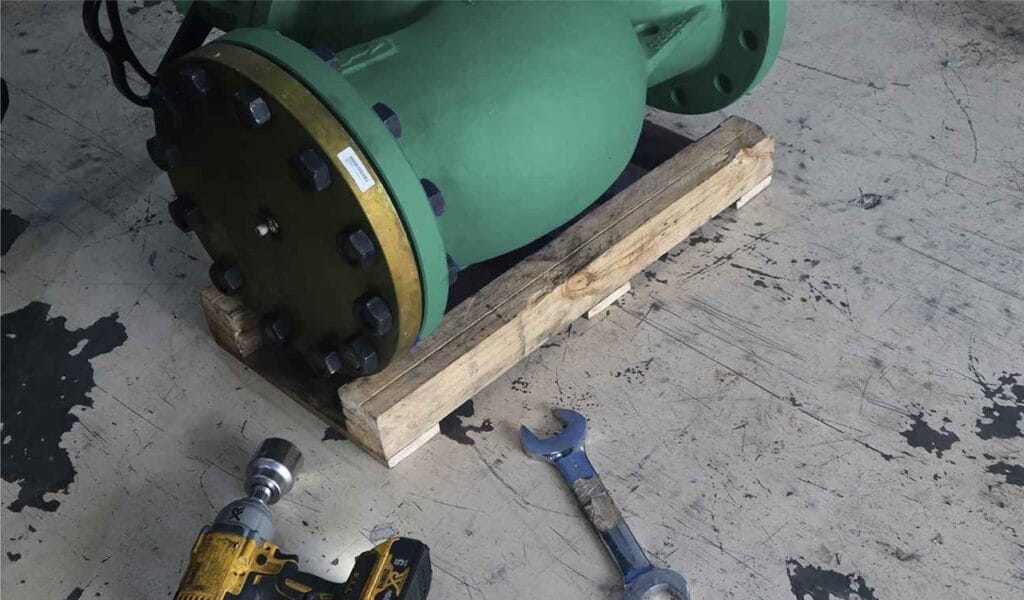

5. Replace Worn-Out Parts Promptly

- Why It’s Important: Worn-out components like seals, gaskets, or O-rings can lead to leaks or valve failure.

- What to Do: Keep an inventory of spare parts for quick replacements. Replace parts as soon as signs of wear are detected.

- Pro Tip: Use high-quality replacement parts from trusted manufacturers like Weissmiller to ensure compatibility and durability.

Why Choose PT Edelweiss Utama Karya?

As a leading supplier in the valve industries, PT Edelweiss Utama Karya provides high-quality Weissmiller valves designed for durability and optimal performance. Our team of experts is always ready to assist you with maintenance tips, technical support, and premium valve solutions tailored to your needs.

Call to Action

Need high-quality valves or maintenance services for your industrial systems? Visit our website or contact our team for more information. Get genuine Weissmiller products only at PT Edelweiss Utama Karya!