In the valve industries, selecting the right type of valve is crucial for ensuring optimal performance, efficiency, and safety in your piping systems. As a trusted supplier of high-quality industrial valves, PT Edelweiss Utama Karya offers a wide range of Weissmiller valves, including ball valves, gate valves, and globe valves. In this article, we will explore the differences between these three common valve types, their applications, and how to choose the right one for your needs.

Ball Valve

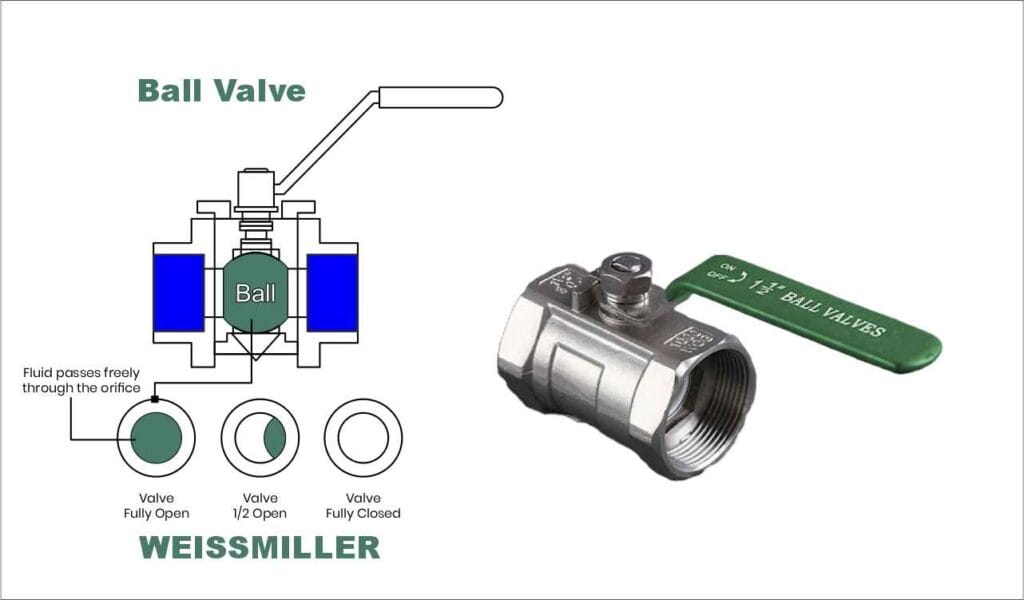

1. Ball Valve

A ball valve is a quarter-turn valve that uses a hollow, perforated, and pivoting ball to control the flow of fluids. When the ball’s hole is aligned with the flow, the valve is open; when it is perpendicular, the valve is closed.

Key Features:

- Operation: Quarter-turn (90-degree rotation) for quick opening and closing.

- Design: Simple and compact.

- Sealing: Excellent sealing capability with minimal leakage.

- Flow Control: Suitable for on/off control, not ideal for throttling.

Advantages:

- Fast and easy to operate.

- Durable and low maintenance.

- Suitable for high-pressure and high-temperature applications.

Applications:

- Oil and gas pipelines.

- Water treatment systems.

- Chemical processing industries.

Keywords: ball valve in valve industries, Weissmiller ball valve

Gate Valve

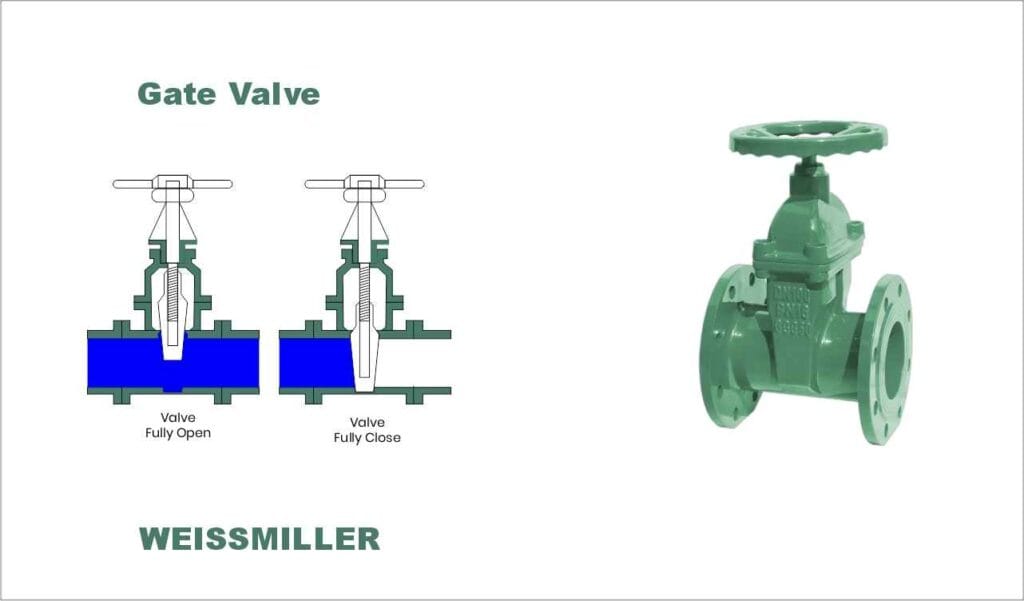

2. Gate Valve

A gate valve is a linear motion valve that uses a gate or wedge to control the flow of fluids. It is primarily designed for on/off control and is not suitable for throttling.

Key Features:

- Operation: Linear motion (raising or lowering the gate).

- Design: Taller and bulkier compared to ball valves.

- Sealing: Provides a tight seal when fully closed.

- Flow Control: Not recommended for flow regulation due to potential damage to the gate and seat.

Advantages:

- Minimal pressure drop when fully open.

- Suitable for high-temperature and high-pressure applications.

- Provides a straight-through flow path.

Applications:

- Water distribution systems.

- Steam systems.

- Slurry and viscous fluid handling.

Keywords: gate valve in valve industries, Weissmiller gate valve

Globe Valve

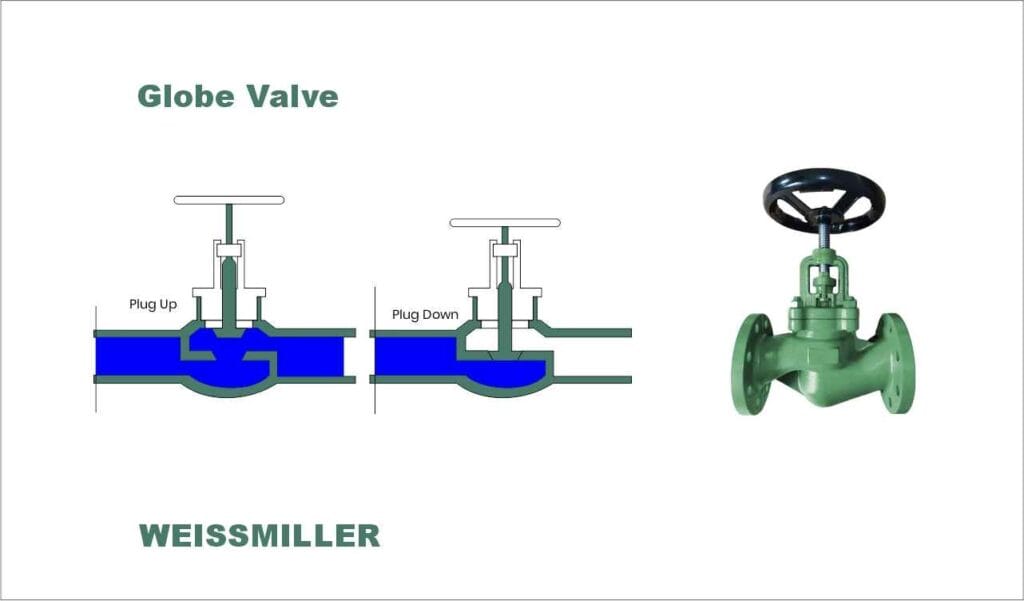

3. Globe Valve

A globe valve is a linear motion valve designed for precise flow control and throttling. It uses a disc that moves up and down to regulate fluid flow.

Key Features:

- Operation: Linear motion (raising or lowering the disc).

- Design: Spherical body with an internal baffle.

- Sealing: Good sealing capability, but not as tight as ball or gate valves.

- Flow Control: Ideal for throttling and regulating flow.

Advantages:

- Excellent for precise flow control.

- Can handle high-pressure applications.

- Suitable for frequent operation.

Applications:

- Cooling water systems.

- Fuel oil systems.

- Chemical and process industries.

Keywords: globe valve in valve industries, Weissmiller globe valve

Comparison of Ball Valve, Gate Valve, and Globe Valve

To help you choose the right valve, here’s a quick comparison:

| Feature | Ball Valve | Gate Valve | Globe Valve |

|---|---|---|---|

| Operation | Quarter-turn (90°) | Linear motion | Linear motion |

| Flow Control | On/Off | On/Off | Throttling/Regulating |

| Sealing | Excellent | Excellent | Good |

| Pressure Drop | Low | Very Low | Moderate to High |

| Maintenance | Low | Moderate | High |

| Applications | High-pressure, high-temperature systems | Water, steam, slurry systems | Precise flow control systems |

How to Choose the Right Valve

Choosing the right valve depends on your specific application and requirements. Here are some factors to consider:

- Flow Control Needs:

- Use a ball valve for quick on/off control.

- Use a gate valve for minimal pressure drop in fully open or closed positions.

- Use a globe valve for precise flow regulation and throttling.

- Pressure and Temperature:

- Ball valves and gate valves are suitable for high-pressure and high-temperature applications.

- Globe valves are ideal for systems requiring precise control under varying pressures.

- Maintenance and Durability:

- Ball valves require less maintenance and are highly durable.

- Gate valves are durable but may require more maintenance due to their design.

- Globe valves may need frequent maintenance due to wear and tear from throttling.

- Space Constraints:

- Ball valves are compact and ideal for tight spaces.

- Gate valves are taller and may require more installation space.

- Globe valves have a bulky design and need adequate space for installation.

Why Choose Valves from PT Edelweiss Utama Karya?

As the official distributor of Weissmiller, PT Edelweiss Utama Karya provides high-quality ball valves, gate valves, and globe valves designed for reliability and efficiency. Our products are trusted by industries worldwide for their performance and durability. We also offer technical support and genuine spare parts to ensure your systems operate smoothly.

Conclusion

Understanding the differences between ball valves, gate valves, and globe valves is essential for selecting the right valve for your application. Whether you need quick on/off control, minimal pressure drop, or precise flow regulation, PT Edelweiss Utama Karya has the perfect valve industries solution for you. Choose Weissmiller valves for unmatched quality and performance.

Call to Action

Looking for high-quality ball valves, gate valves, or globe valves? Visit our website or contact our team for more information. Choose Weissmiller products only at PT Edelweiss Utama Karya for unmatched performance and reliability!